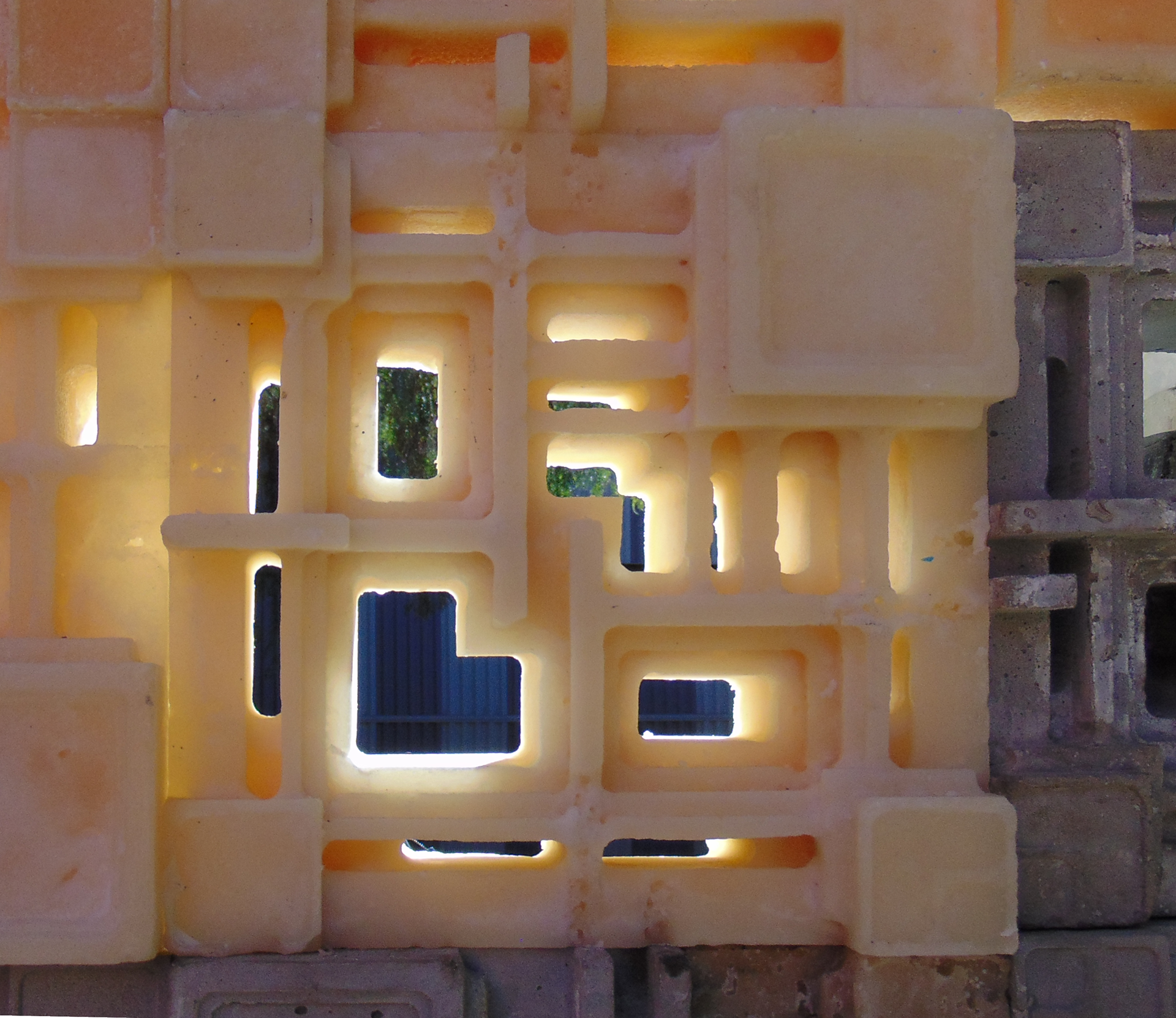

create a more sustainable textile block in the FLW way.

Chester Tumbos and I were in a team to research materials. instead of adding aggregates to simply take up space in the concrete, we chose to completely remove the concrete, because it accounts for the highest impact on the environment. We decided to research one of our shared interests, baking, and landed on sugar blocks.

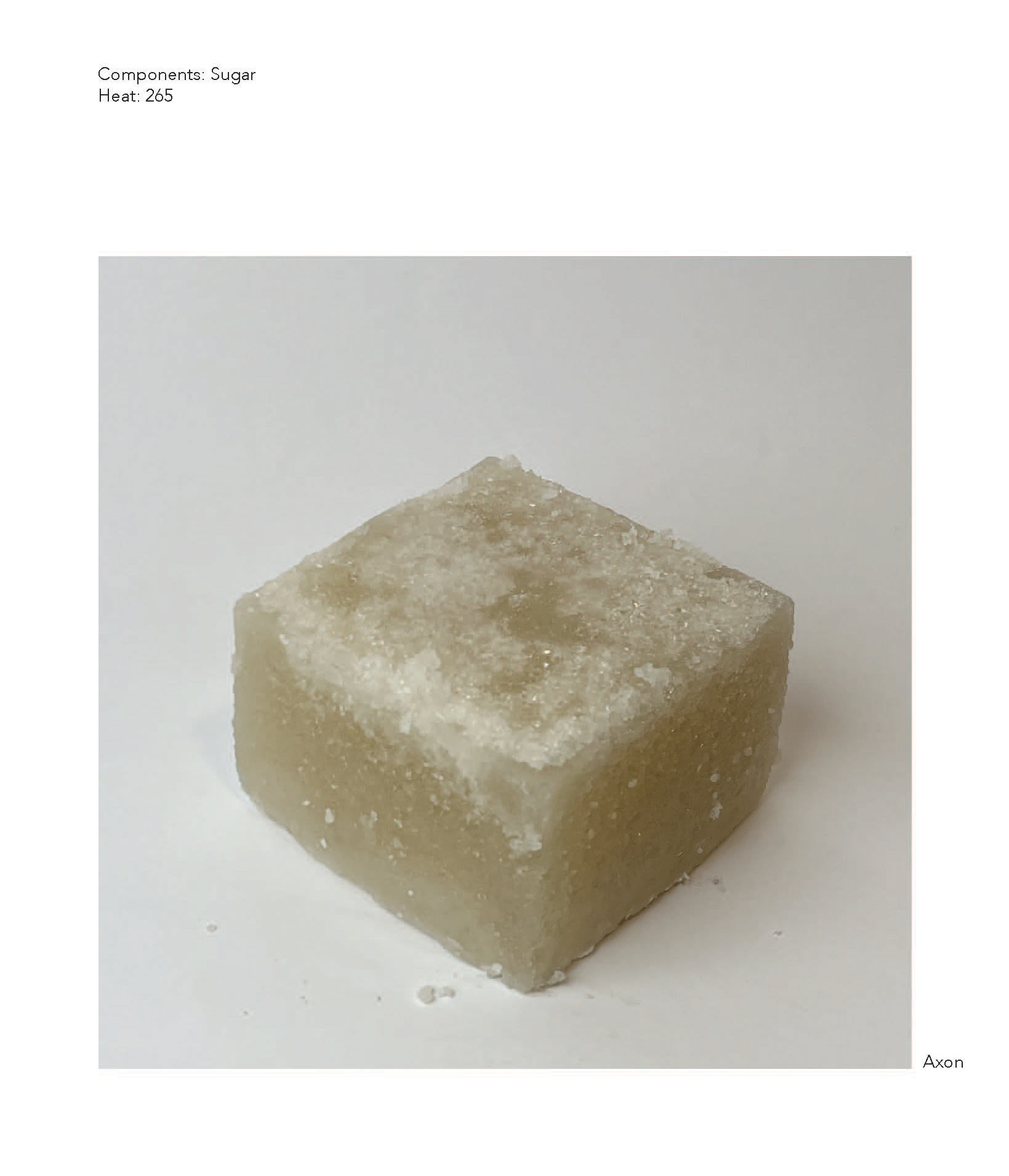

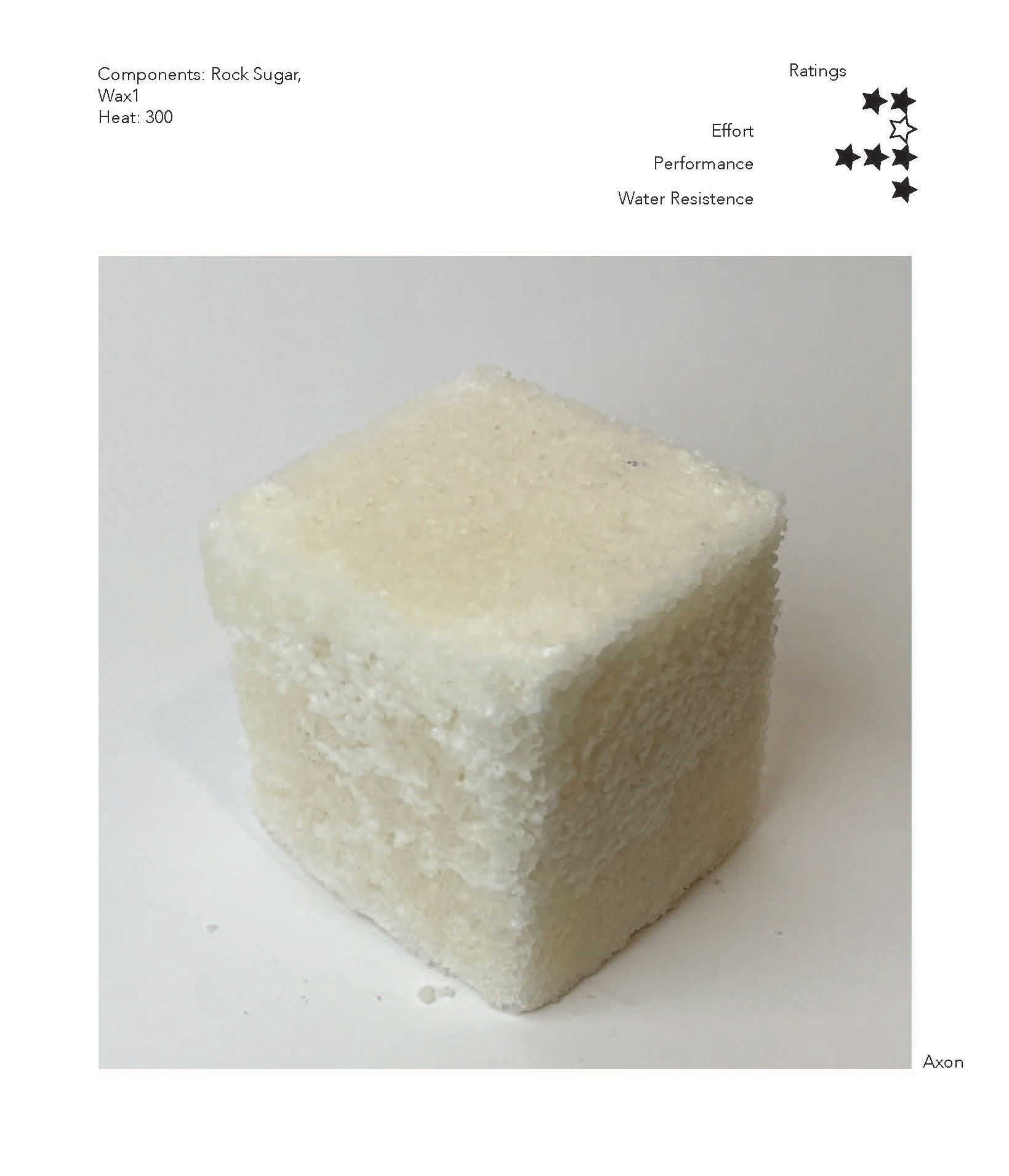

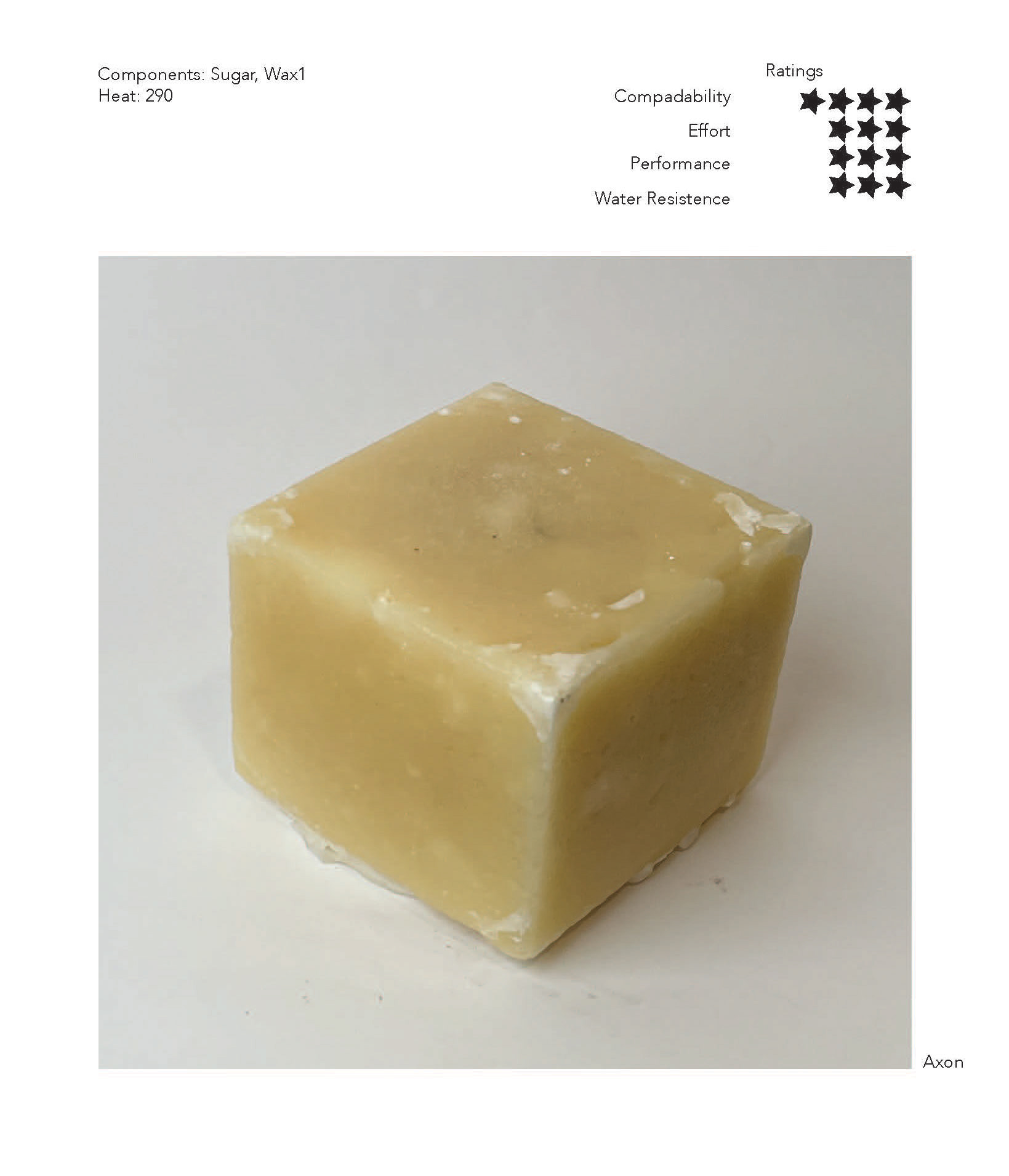

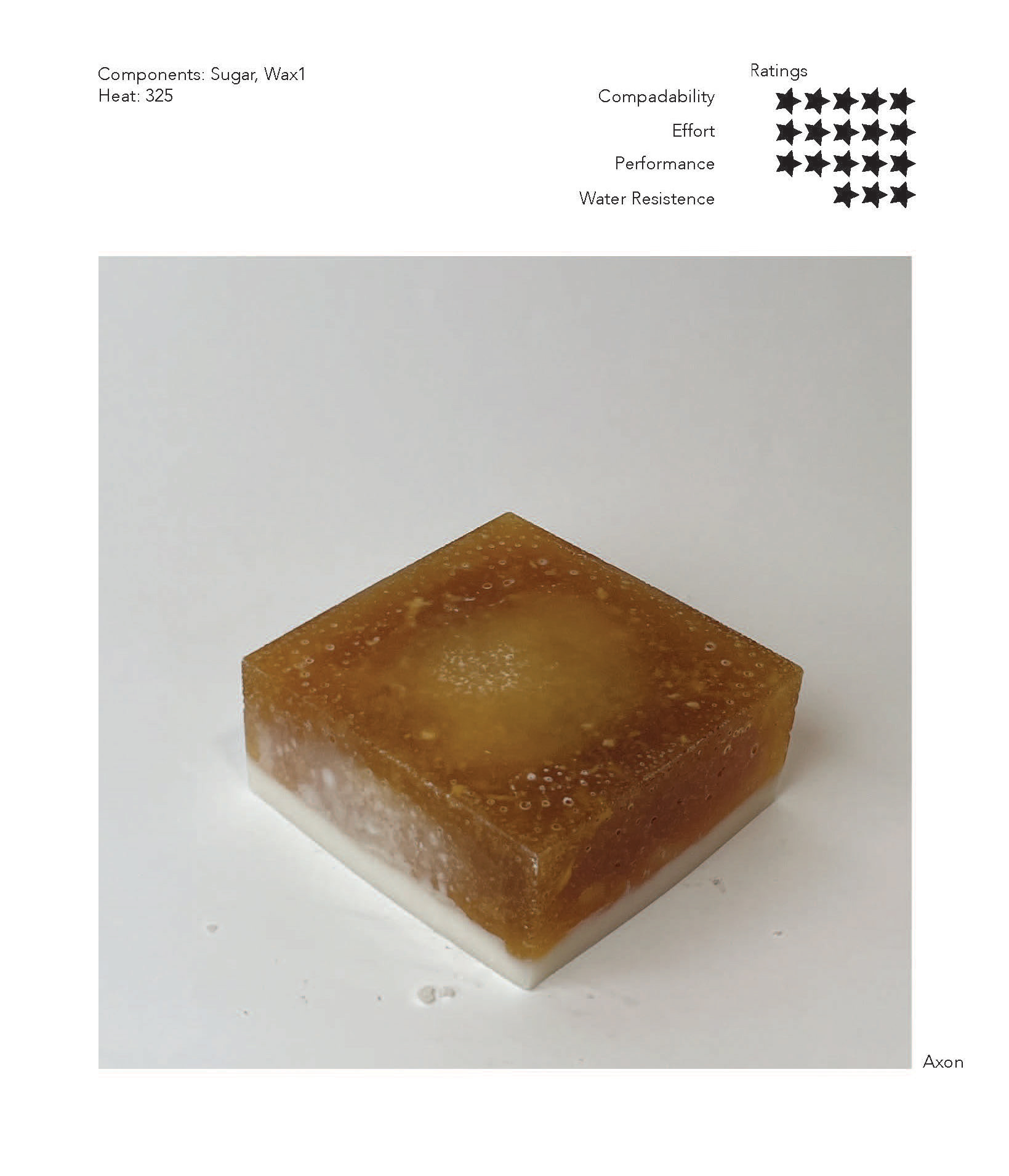

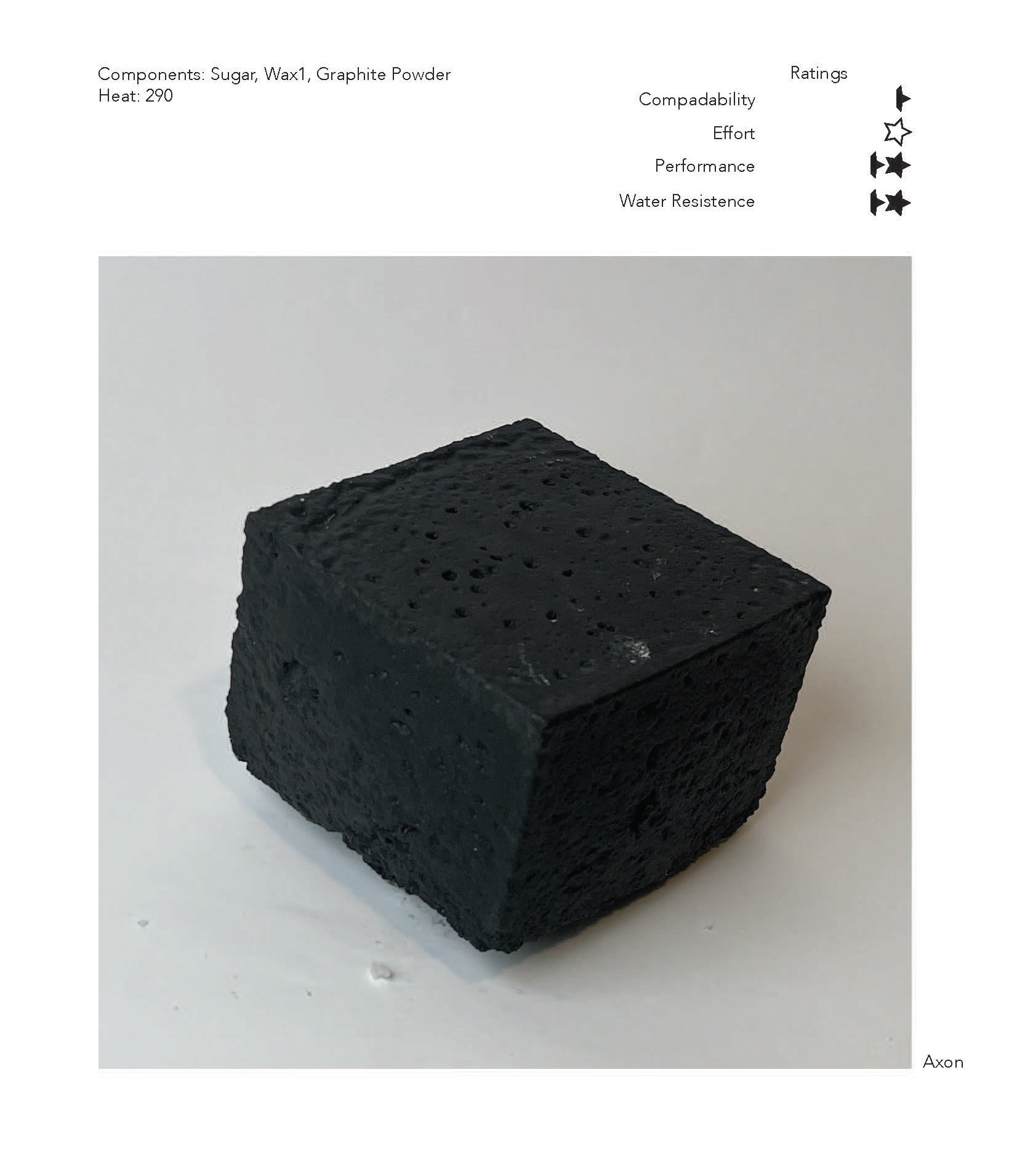

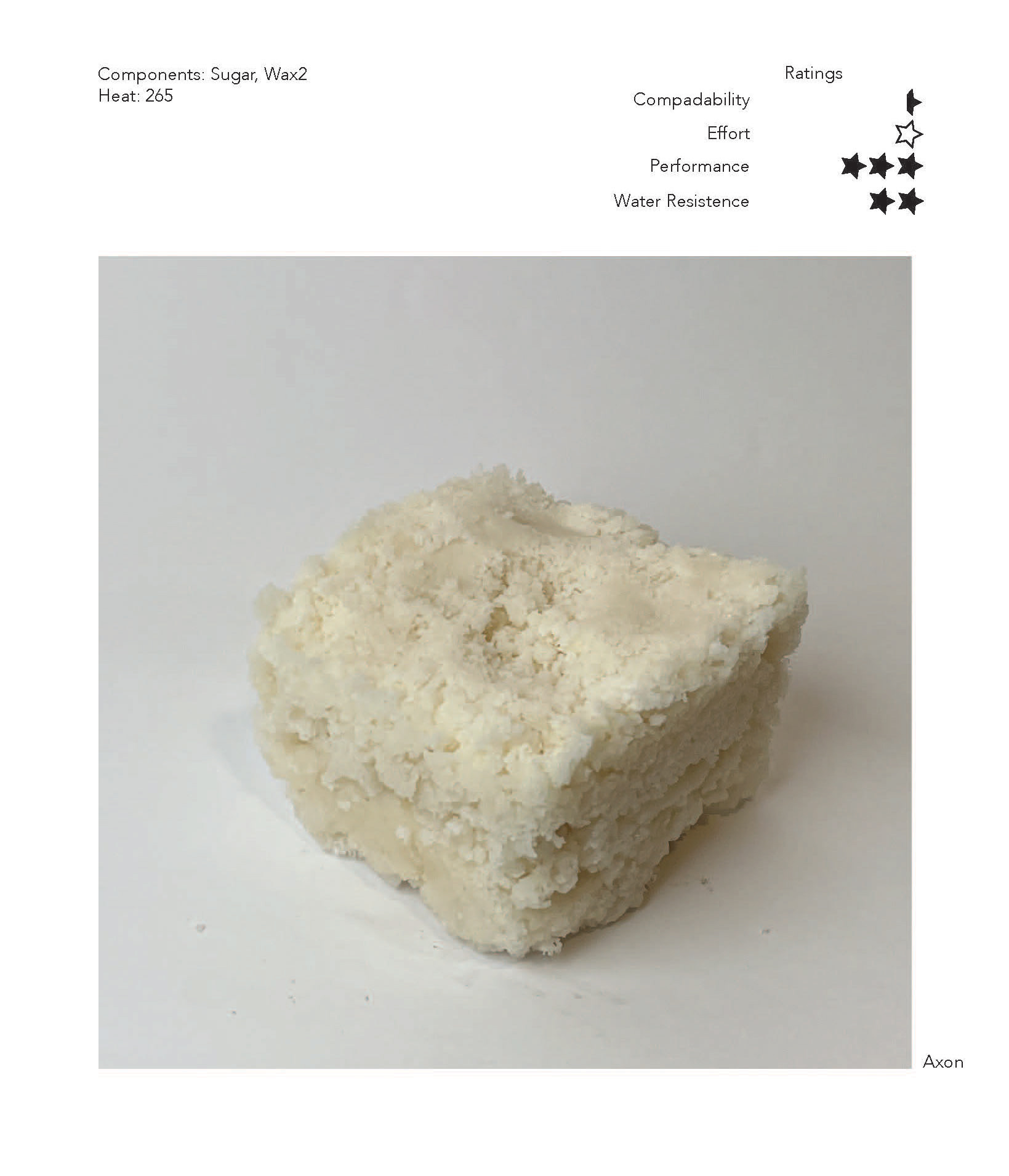

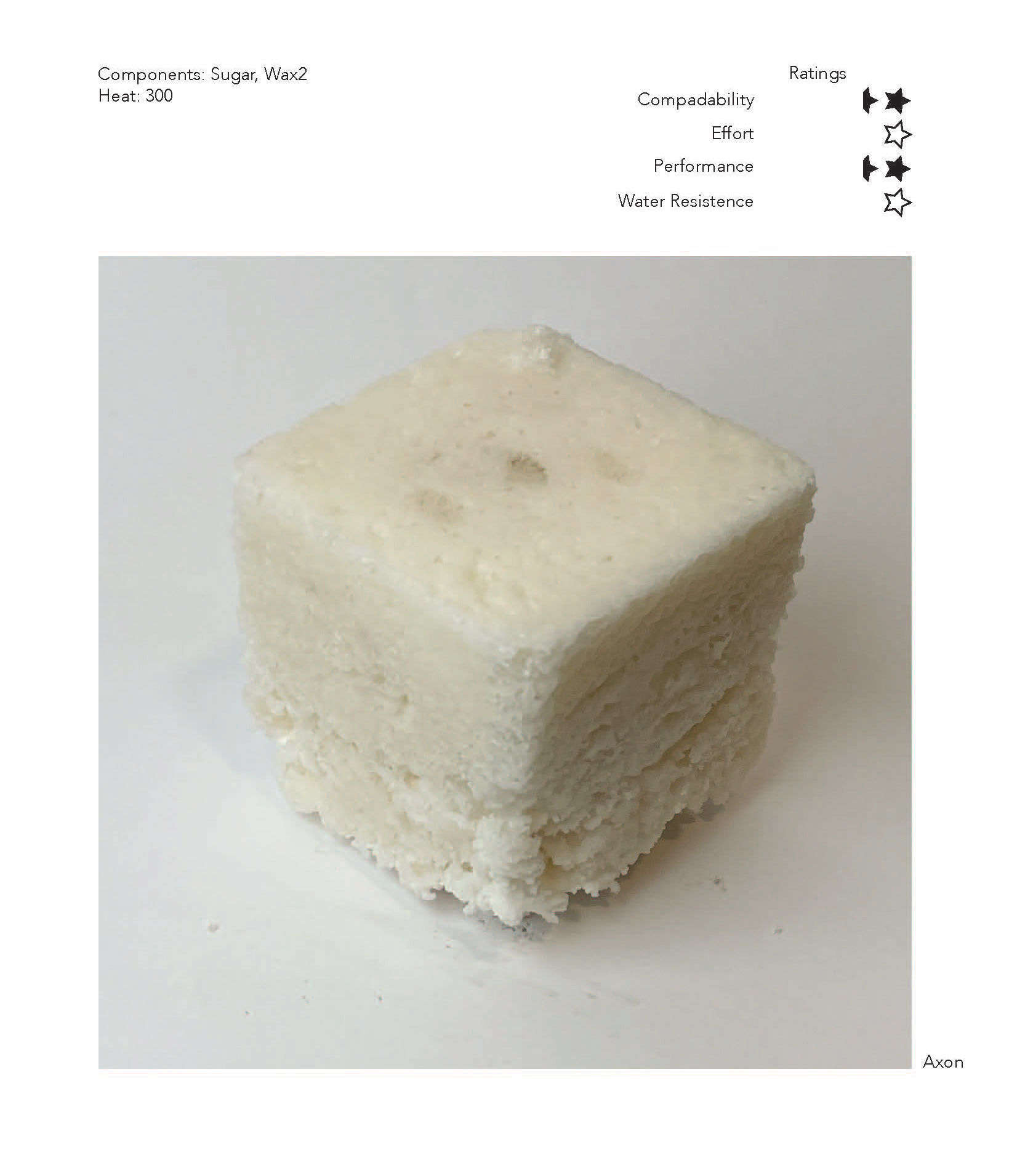

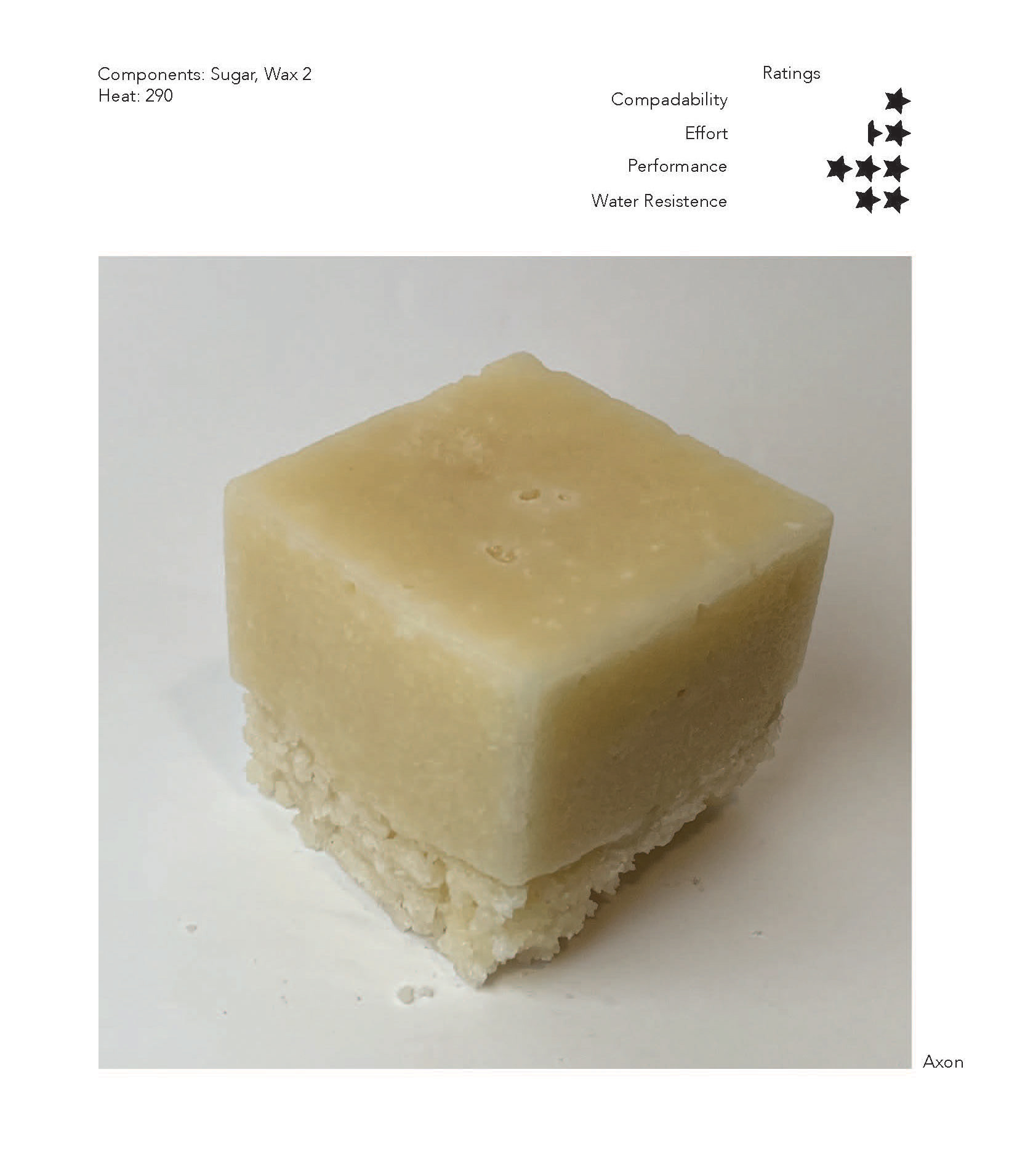

By heating sugar to between 265 and 300, until molten, we created moldable sugar (candy) blocks. adding wax significantly increased water and pest repellence.

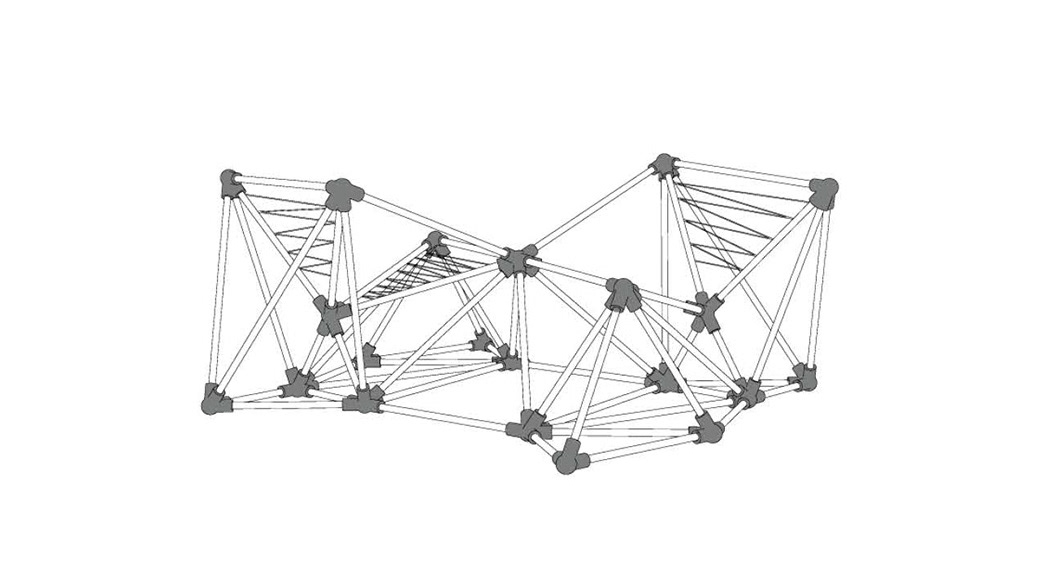

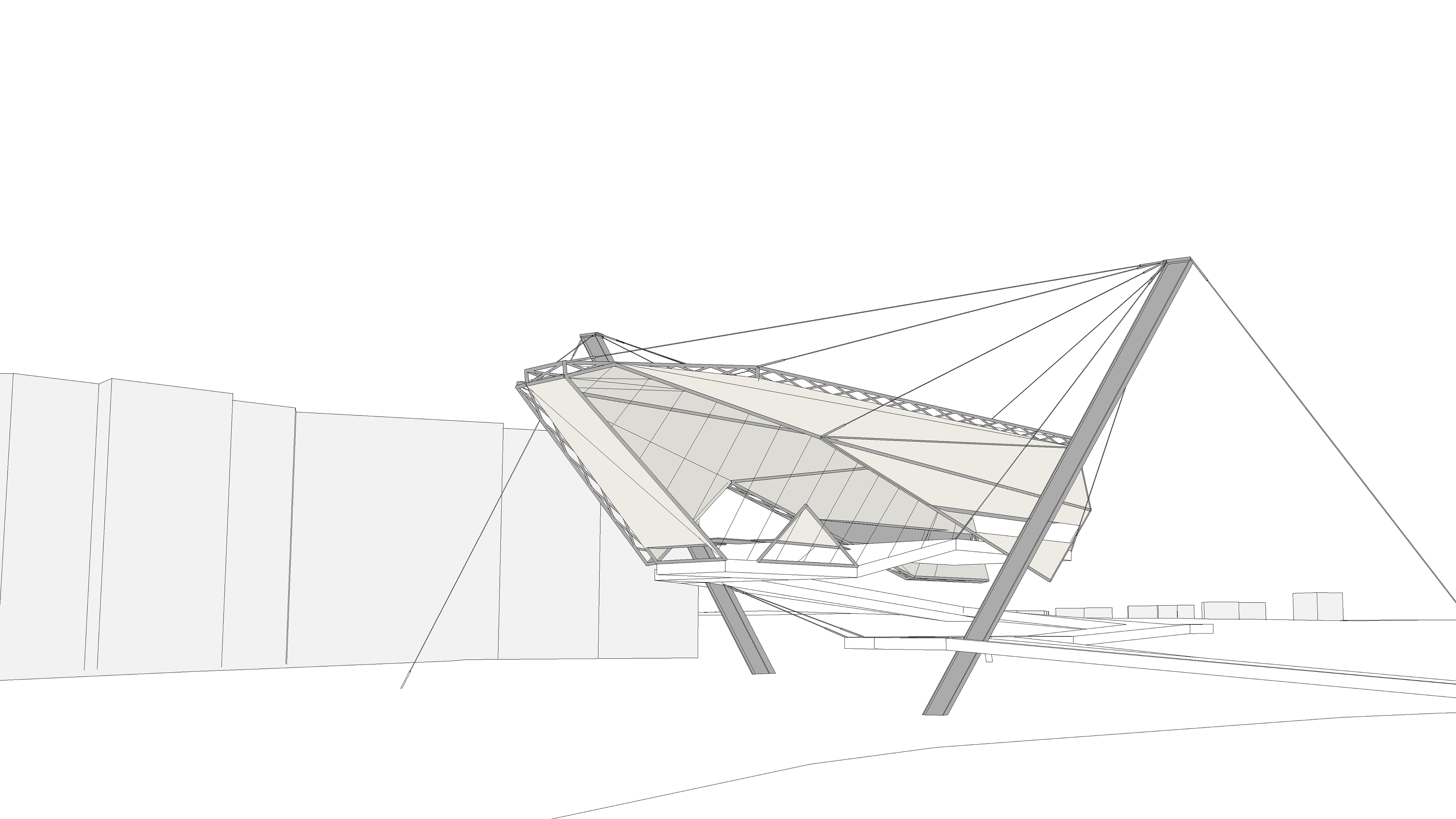

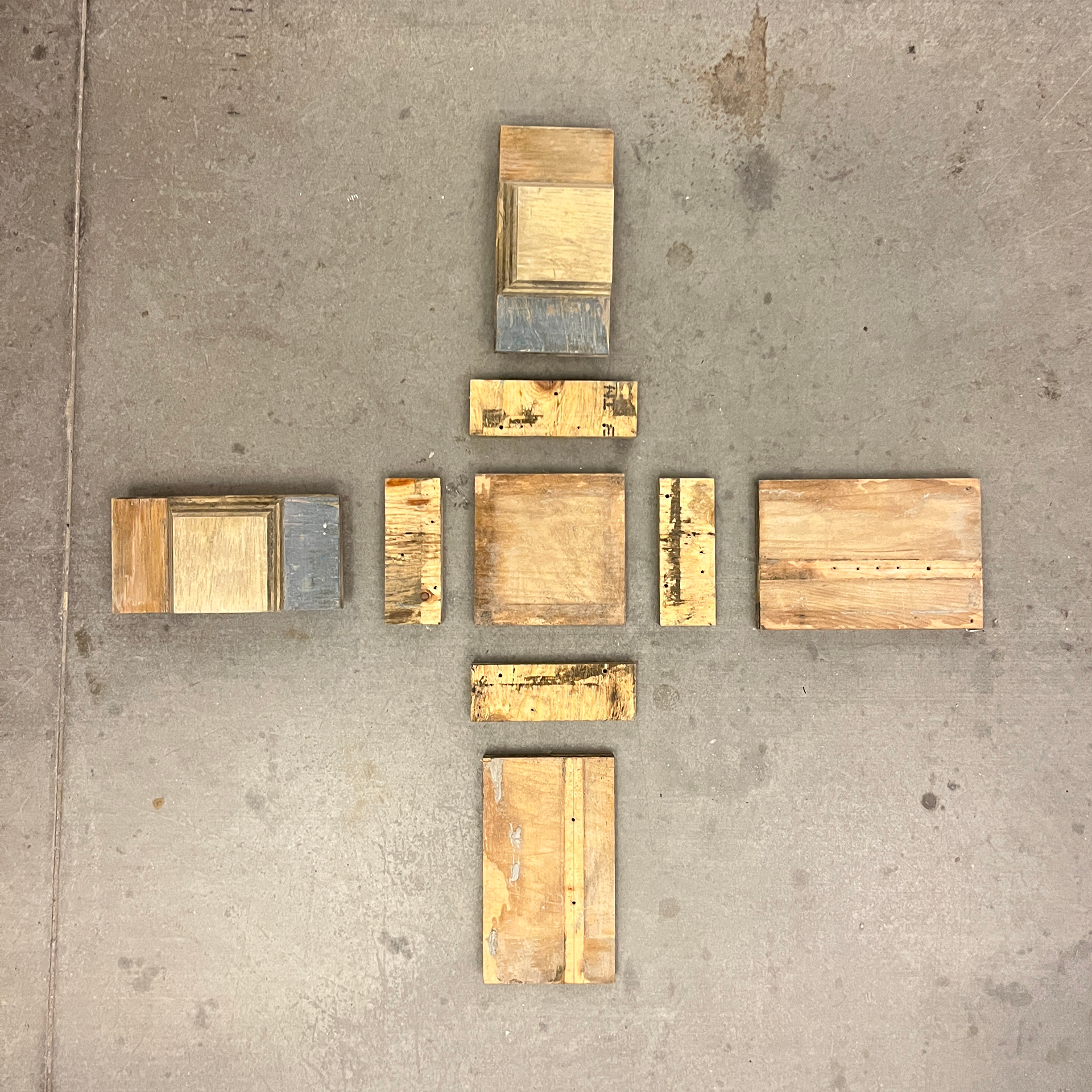

Another way we demonstrated environmental consideration was in the structural system. rather than using grout and rebar, this structure can be disassembled into parts and moved (or scaled) to a new site.

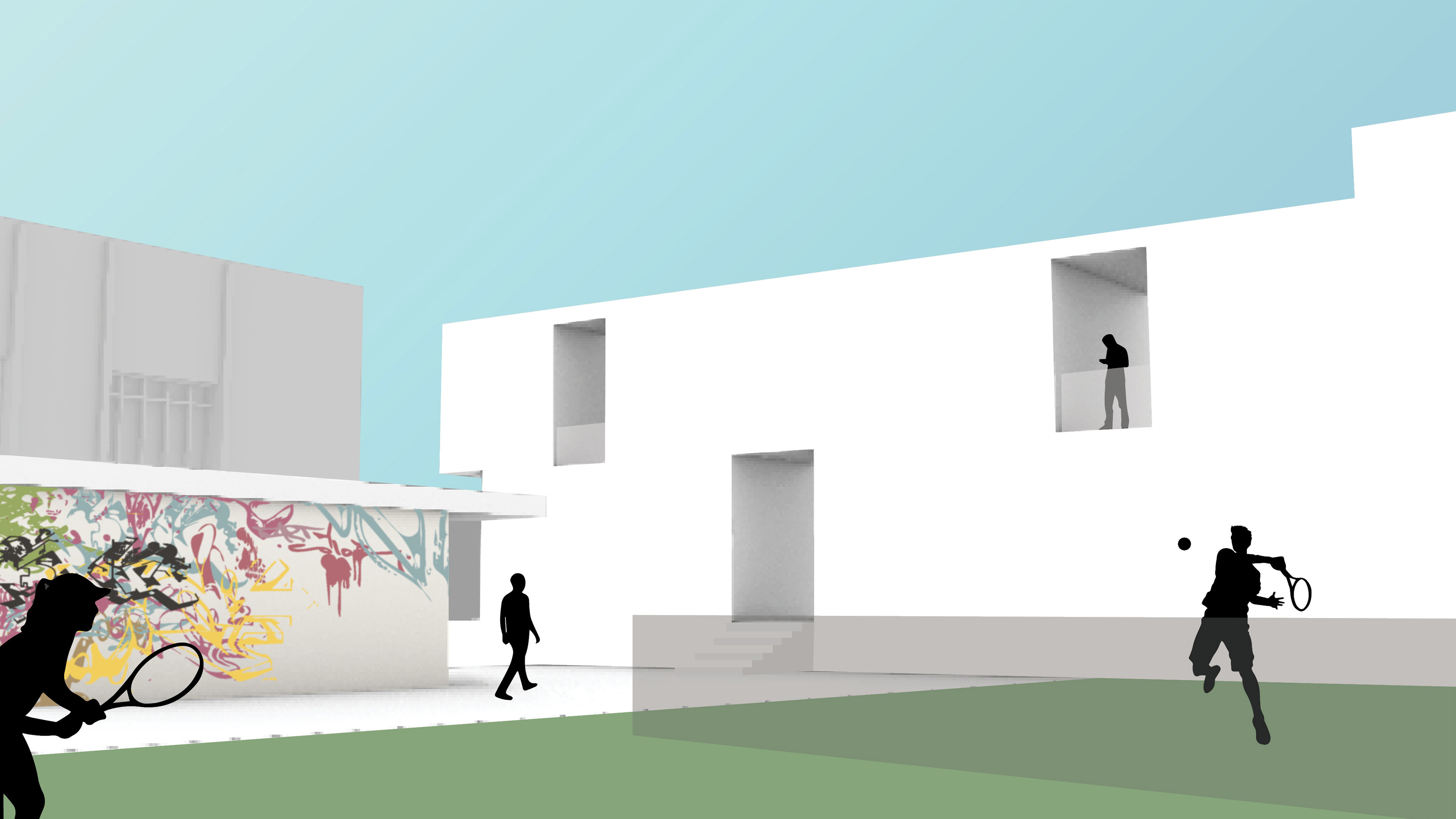

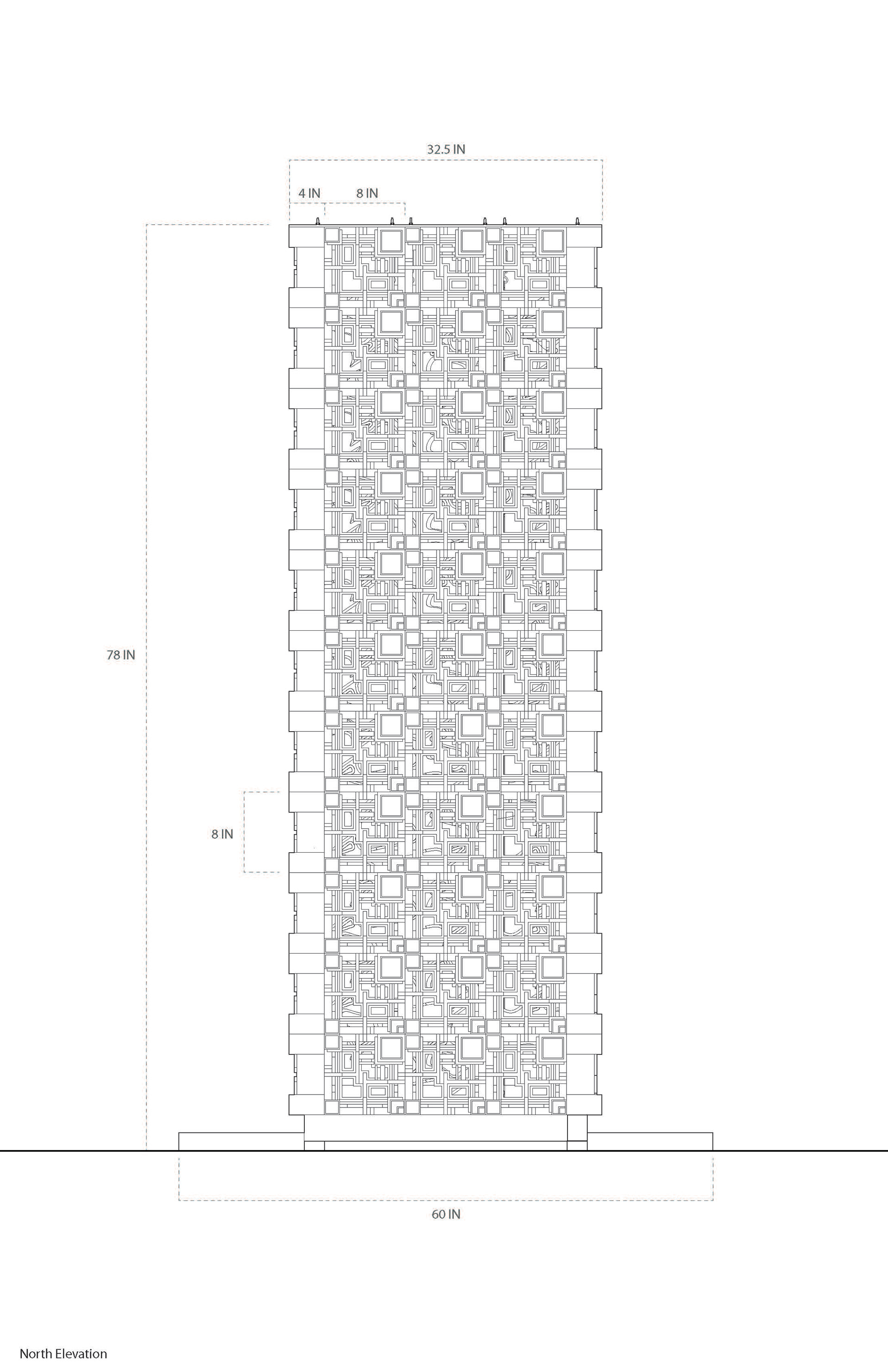

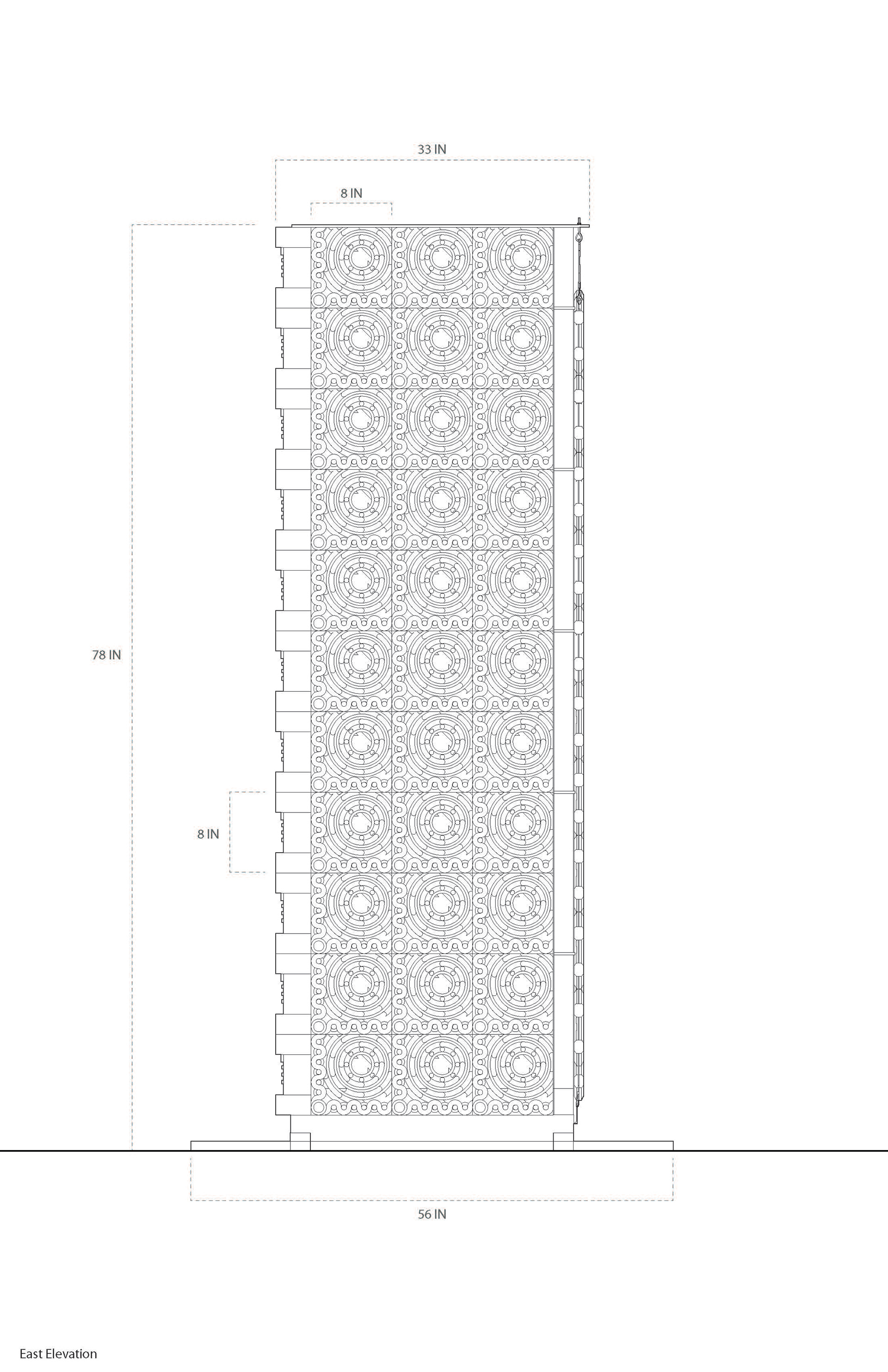

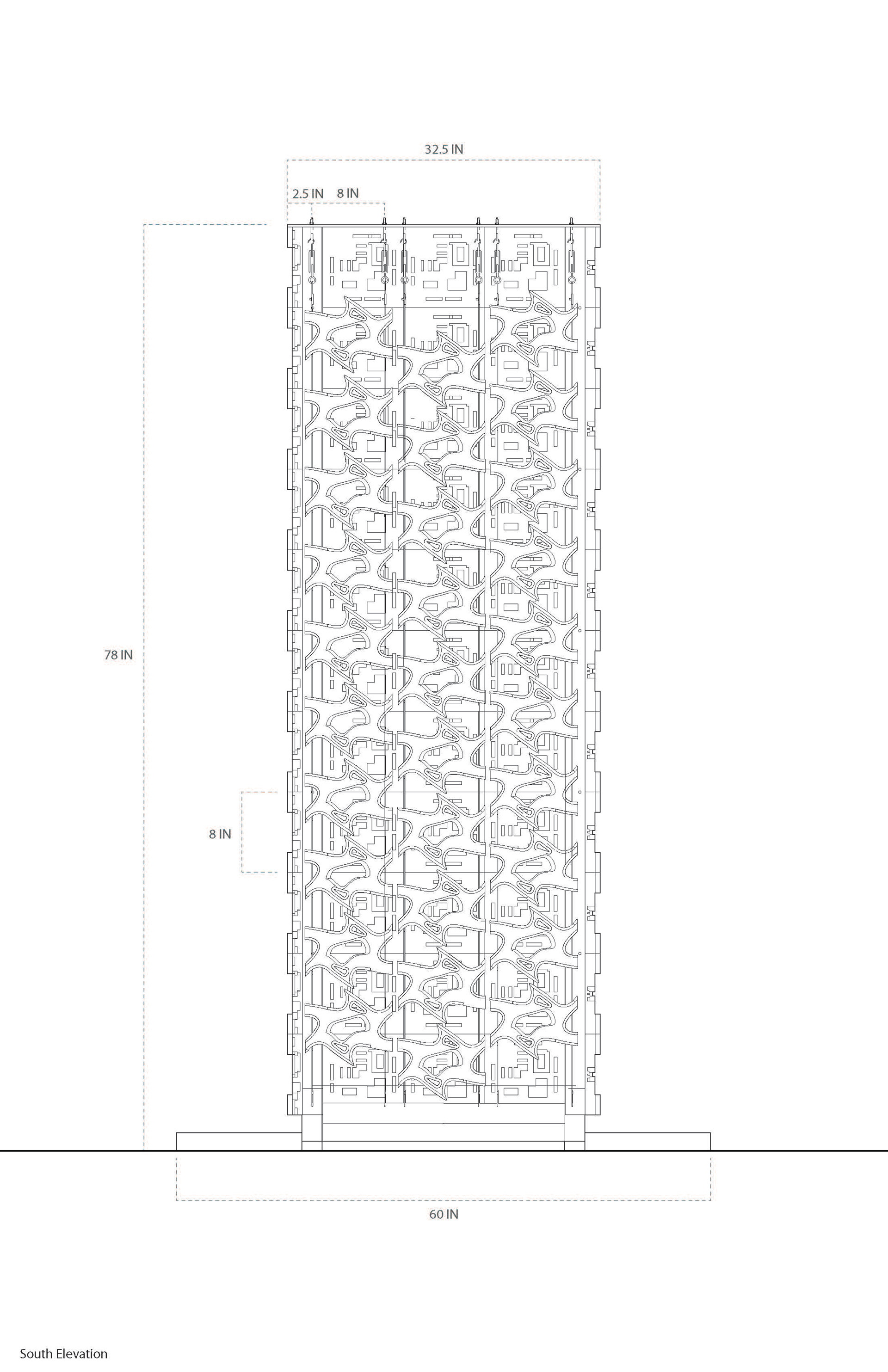

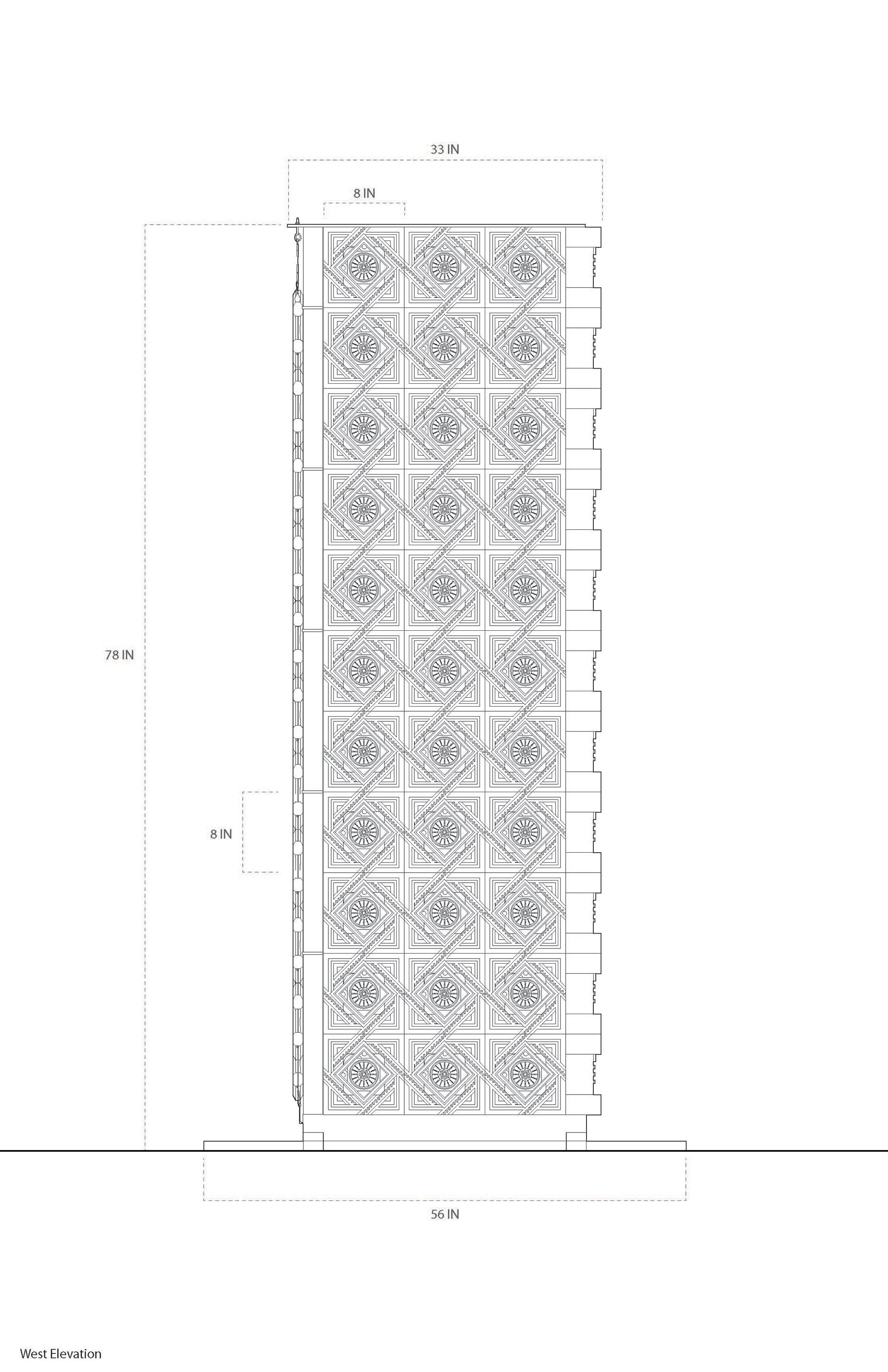

Chester and my blocks are the northern side (The sugar side) Armen's on the west (diamond shaped) Alex's on the east (circle shaped) and kimia's ceramics on the south. This project was a combination of 7 groups from 2 separate classes (Jones and Stein)

our full team: Chester Tumbos, Angie Berardi, Kimia Sadat Mirelmi, Linnette Jambazian, Armen Karapetyan, Alexander Chaidez, Joly Mikhaiel, and I

Architecture build 6 at Woodbury University (2023), Prof. Benjamin jones

combined with Prof. Joshua Stein's ceramics class

NW

NE

SE

SW

3d printed spacer visible in beige

Sugar and Concrete Mixed

Shattered sugar block

shattered concrete block

1 unit made by kimia

After 5 weeks with heavy rainfall, much of the blocks had melted with bees and ants feasting!

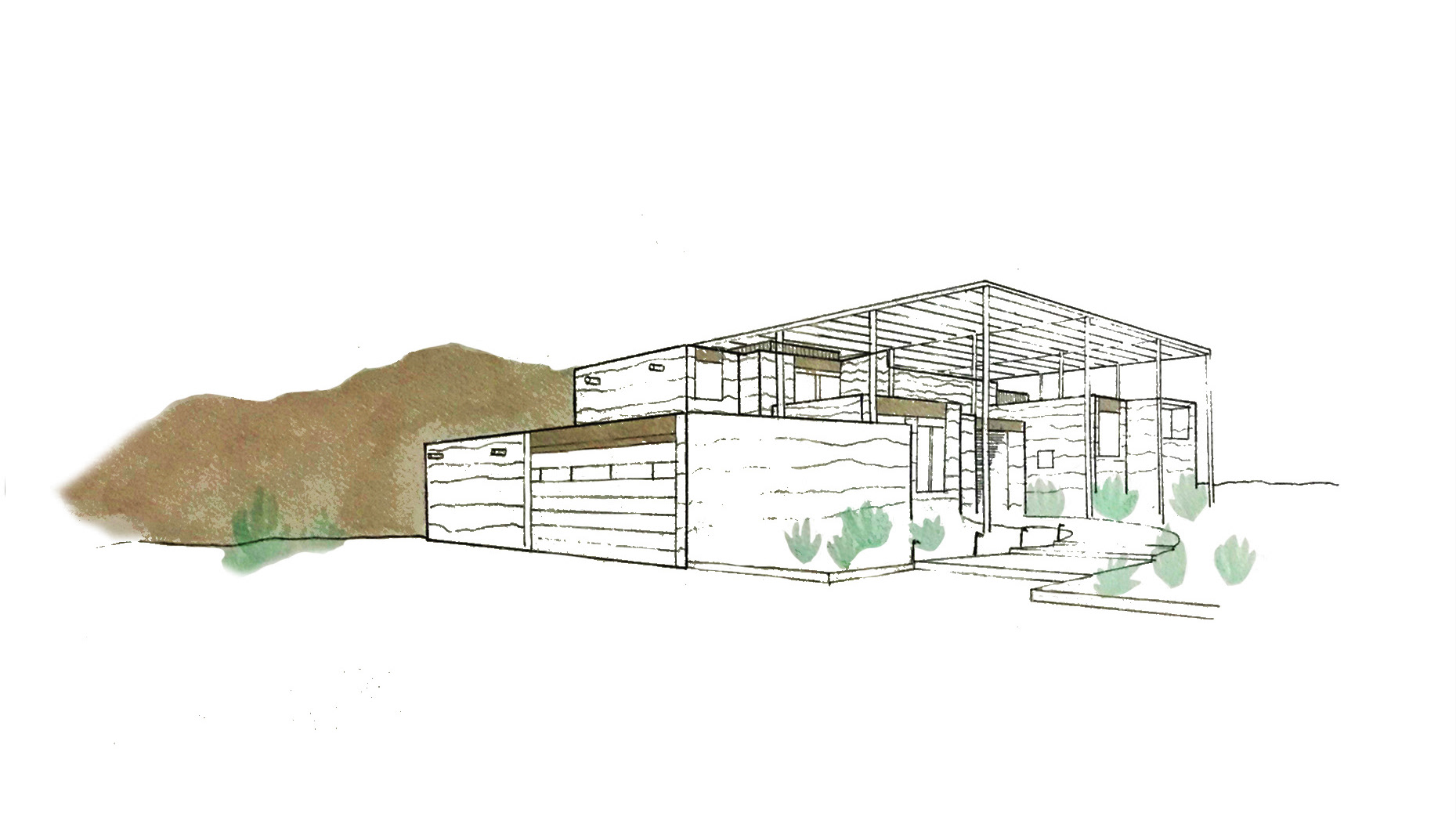

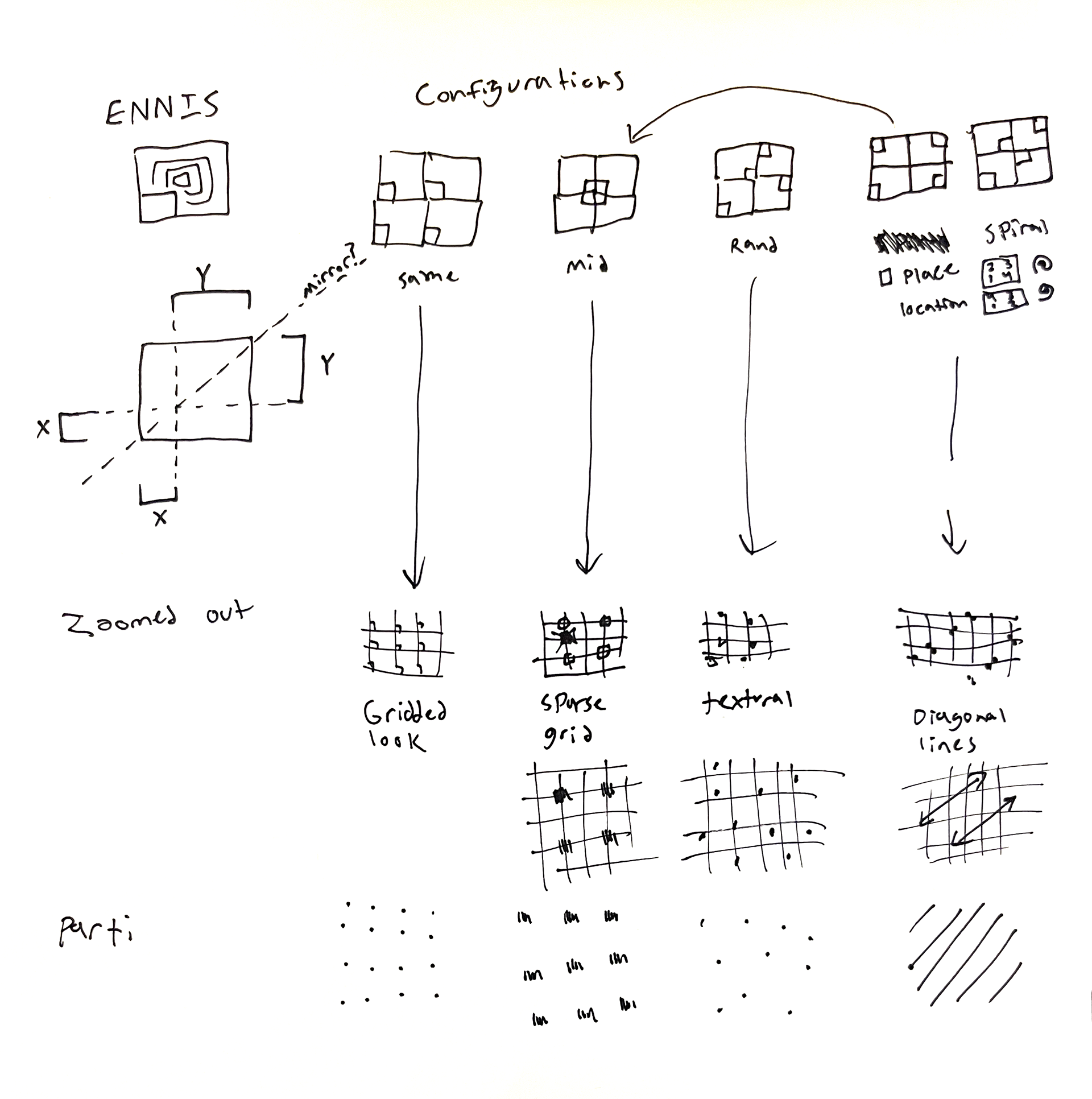

Early study of the ennis block's asymmetry showed a range of possible patterns achievable by rotation around the large space. This informed my sugarcane collages to end up with the left design.

our chosen pattern was "spiral"

MAterial research

everyone's favorite

silicone mold for our block

Marks from the CNC show through the silicone and into the concrete and sugar

Mold for corner pieces (3 were made)

mold v2

mold v1

v1 mold

v2 mold

The corner molds were tough to get right due to the concrete sticking to the mold no matter how much release / sealant was used. in the end we used green rigid insulation foam for the small pieces. these were meant to tear out with every block instead of breaking the mold every time.

This is how the Ceramics would have looked

Alex, Me, Angie, linnette, chester, armen

Progress pictures

Jose helping!

Griffin helping!

Initial test of structure